E-mail:

info@synotherm.cn

E-mail:

info@synotherm.cn

Icy LI

Email:icy@synotherm.cn

Skype:lingflame

Tel: +86 18570765521

Dan LIU

Email:dan@synotherm.cn

Skype:live:liudan_1

Tel: +86 18670708666

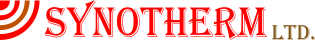

ATMOSPHEER MUFFLE FURNACE

OUTLOOKING DETAILS

MODEL BR-17AM-1

HEATING ZONE | SIZE WEIGHT | DELIVERY DATE |

100x100x100mm | 600mm.X500mmX1210mm 130KG | WITHIN 10 DAYS AFTER RECEIVE YOUR PAYMENT |

MODEL | MAX TEMPERATURE | WORKING TEMP | HEATING ELEMENT | TEMP MEASUREMENT |

BR-17AM | 1700℃ | 1600℃ | Silicon molybdenum rod | Thermocouple |

技术参数